- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

She is in charge of the whole manufacturing chain of these micro-devices, after definition with the applicant. The main steps in the manufacturing of an impression are :

- shaping of the mask representing the circuit

- deposition of the photosensitive resin on a 3" silicon plate

- UV exposure and revelation of the circuit imprint

This step can be done in two ways: exposure through a mask, or direct laser writing, using a device purchased in 2019 (Dilase by Kloé) and if the applicant wants a finished product...

- molding of PDMS on this impression

- gluing on glass slide

- installation of the fluidic connection

|

|

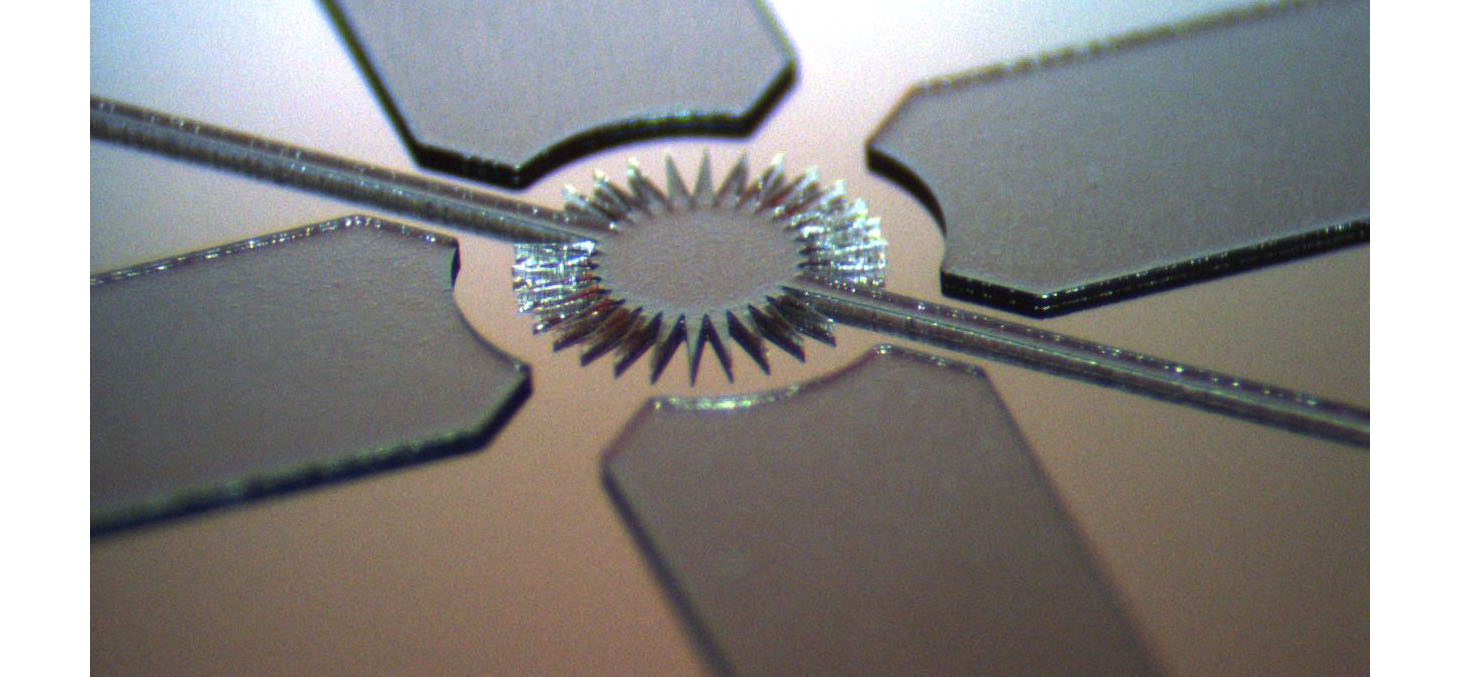

Below is an example of a SU8 mold before molding with PDMS resin (SU8 thickness of 140microns)

Contact

Scientific Manager

Gwennou COUPIER

Office 309

Tel: 04 76 51 47 63

gwennou.coupier univ-grenoble-alpes.fr (gwennou[dot]coupier[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (gwennou[dot]coupier[at]univ-grenoble-alpes[dot]fr)

Deputy Scientific Manager

Philippe MARMOTTANT

Office 330

Tel: 04 76 51 43 33

philippe.marmottant univ-grenoble-alpes.fr (philippe[dot]marmottant[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (philippe[dot]marmottant[at]univ-grenoble-alpes[dot]fr)

Technical Team

Direct photolithography development

Mathilde VAN MELLE-GATEAU

Office 303

Tel: 04 76 63 58 71

mathilde.gateau univ-grenoble-alpes.fr (mathilde[dot]gateau[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (mathilde[dot]gateau[at]univ-grenoble-alpes[dot]fr)

Technical manager

Danièle CENTANNI

Office 201

Tel: 04 76 51 47 66

daniele.centanni univ-grenoble-alpes.fr (daniele[dot]centanni[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (daniele[dot]centanni[at]univ-grenoble-alpes[dot]fr)

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn