- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

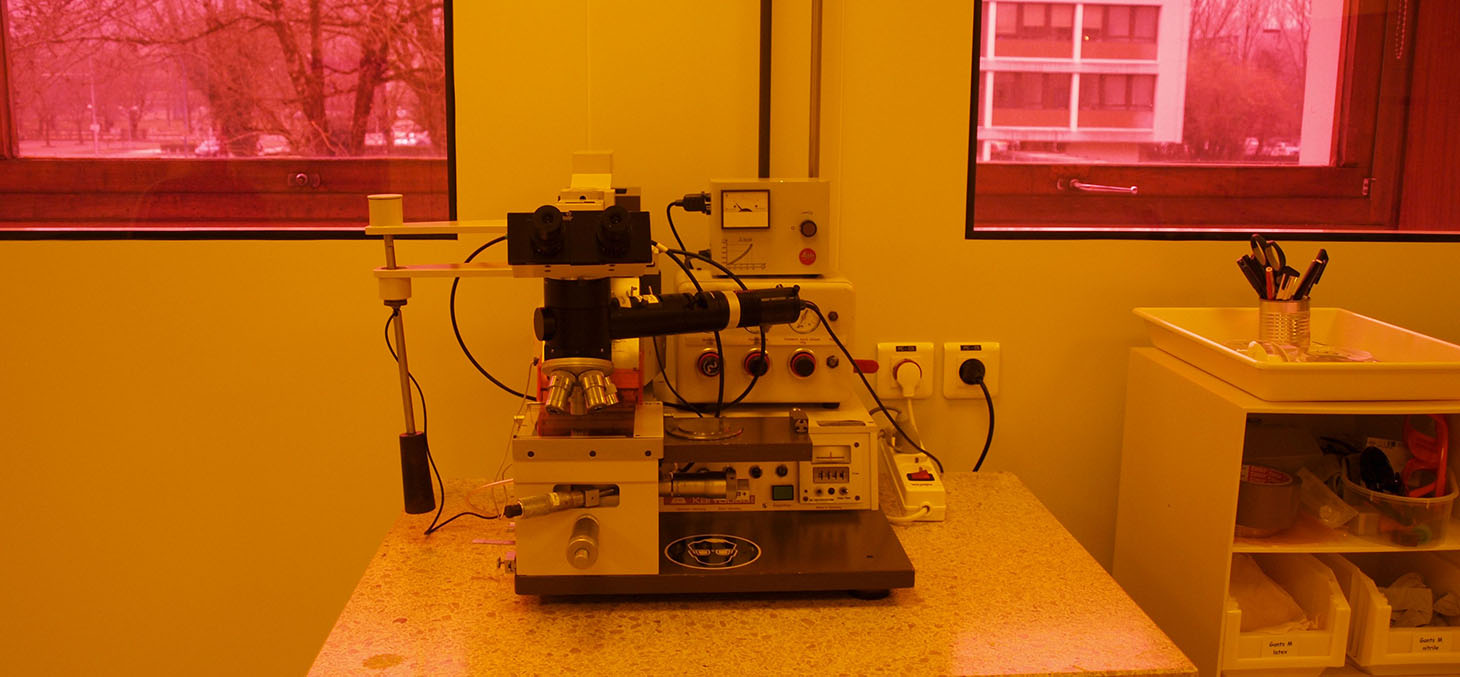

All the techniques implemented in the MicroFab platform are installed in a clean room in the LIPhy laboratory. It is ISO 8 cleanliness (class 100 000) and has ISO 5 laminar flow (class 100). The proposed techniques are: photolithography and molding of microfluidic circuits.

The equipment used for photolithography is :

- spincoater TP6000 from Karl Süss with speeds up to 4000 RPM

- programmable hot plate with temperature ramp from Harry Gestigkeit and its PR5 SR programmer which allows to reach a temperature of 200°C

- MJB3 alignment masker from Karl Süss with a maximum plate size of 3 inches

- chemistry fume cupboard for resin development

- direct laser photolithography machine DILASE 250

We offer deposited SU8 resin thicknesses ranging from a few microns to 400 microns from Gersteltec resins (type 1040, 1060, 1070, 1075)

For the molding of microfluidic circuits, we are equipped with a Harrick Plasma cleaning machine which allows us to prepare for bonding wafers up to 4 inches in size. In order to finalize the microfluidic chips we have an oven used for the cross-linking of PDMS and its annealing.

Contact

Scientific Manager

Gwennou COUPIER

Office 309

Tel: 04 76 51 47 63

gwennou.coupier univ-grenoble-alpes.fr (gwennou[dot]coupier[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (gwennou[dot]coupier[at]univ-grenoble-alpes[dot]fr)

Deputy Scientific Manager

Philippe MARMOTTANT

Office 330

Tel: 04 76 51 43 33

philippe.marmottant univ-grenoble-alpes.fr (philippe[dot]marmottant[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (philippe[dot]marmottant[at]univ-grenoble-alpes[dot]fr)

Technical Team

Direct photolithography development

Mathilde VAN MELLE-GATEAU

Office 303

Tel: 04 76 63 58 71

mathilde.gateau univ-grenoble-alpes.fr (mathilde[dot]gateau[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (mathilde[dot]gateau[at]univ-grenoble-alpes[dot]fr)

Technical manager

Danièle CENTANNI

Office 201

Tel: 04 76 51 47 66

daniele.centanni univ-grenoble-alpes.fr (daniele[dot]centanni[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (daniele[dot]centanni[at]univ-grenoble-alpes[dot]fr)

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn