- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

Five agents work full-time on this platform, which consists of a mechanical workshop and a raw materials store.

We respond to requests both from within the laboratory and from outside, from numerous laboratories at CNRS, UGA, Grenoble-INP, CEA, ILL, ESRF, etc. We also work with research-based start-ups. Since 1967, the mechanical platform has always kept pace with technological developments and has been able to adapt to the demands of science.

The platform's strengths are:

- Availability and interaction between requesters and mechanics

- Responsiveness

- Knowledge and expertise in many fields

- Machining of a wide variety of materials

- Staff training

Operation

Depending on the case :

- The requester has questions about how to get his/her result, he/she can drop by the workshop to discuss it with the staff and find a simple solution.

- The requester has detailed and dimensioned drawings (made on software or by hand), he/she can bring them to the workshop for the manufacturing of the parts, or can also send them by mail in PDF format. For some jobs, we ask for a DXF file, to facilitate the programming of the numerical control machines.

In all cases, a quote will be provided and the completion time will be specified.

Team

We are a team of five agents. Over time, machinists have adapted to different technological requirements depending on the field of application. Machining skills are thus used in the fields of medicine, chemistry, biology, vacuum and ultra-high vacuum, lasers, planetology, etc.

All mechanics are accustomed to working in teams and regularly under pressure; they demonstrate particular technical skills and expertise. Their skills are recognized by all the laboratories for which they work.

Equipment

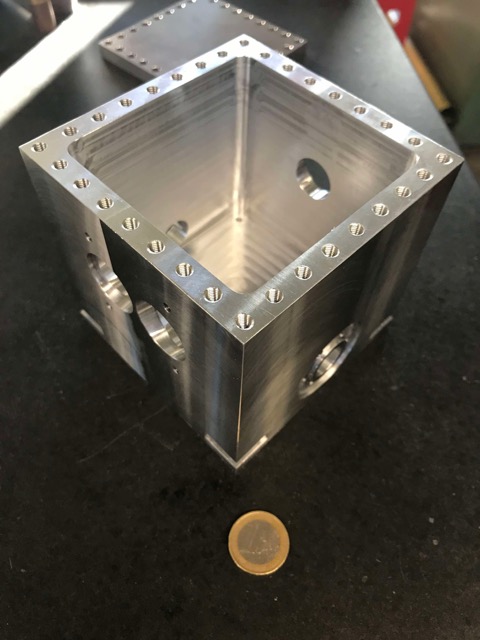

Our mechanical workshop has a wide range of machinery:

- 7 lathes (Cazeneuve, Schaublin, Hernault)

- 4 milling machines (Deckel)

- 1 numerically controlled milling machine (DMG model DMU 50)

- 1 numerically controlled lathe (SOMAB TRANSMAB 250)

- 1 2-metre cut-off saw

- 1 water jet cutter (Wazer)

- 1 5-wire 3D printer (Prusa)

- Other tools: semi-automatic saw, guillotine, press, rolling machine, bending machine, 2 TIG stations, etc.

We machine all kinds of materials:

- Non-ferrous: aluminium, copper, brass, etc.

- Ferrous: stainless steel, steel, etc.

- Plastics: PC, PMMA, POM, PTFE, PEEK, etc.

- More exotic materials: molybdenum, titanium, etc.

Raw materials store

The platform's store contains all the raw materials we need.

There are several categories of materials:

- Non-ferrous: aluminium, brass, copper, etc., available in plates, rounds, tubes and profiles.

- Ferrous: mainly stainless steel in plates and rounds.

- Plastics: PVC, POM, PC, PMMA, PTFE, etc., in plates and rounds.

We have several suppliers who guarantee us competitive prices.

Staff training

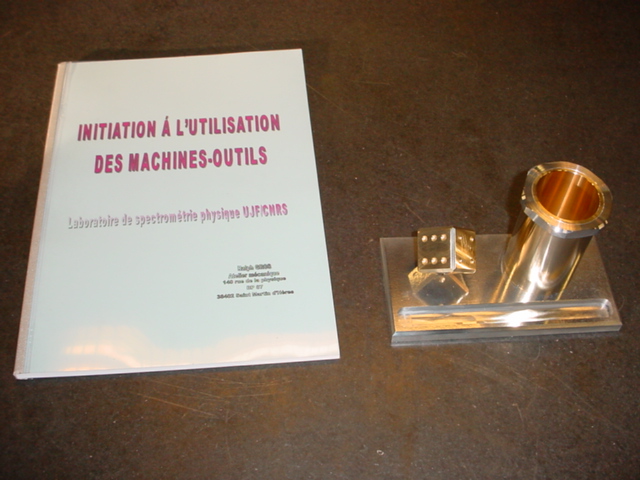

‘Introduction to the use of machine tools’

Since 2003, we have been training higher education staff: universities, INPs and the CNRS.

The training is intended for all non-mechanical staff and lasts 5 days (over 2 weeks). We run between 1 and 3 sessions per year, depending on demand. For technical and safety reasons, we take 4 trainees per session.

At the end of the 5 days, trainees leave with a small assembly that they have built entirely themselves, enabling them to carry out small machining operations in their workplace. In some cases, the training course gives access to the laboratories' self-service workshops.

Between 2003 and 2025, we ran 37 sessions and trained 148 staff members.

Adress

Laboratoire LIPhy - Université Grenoble Alpes

140 rue de la Physique

38400 Saint-Martin-d’Hères

Contact

Ralph GROS

06 16 47 09 96

ralph.gros univ-grenoble-alpes.fr (ralph[dot]gros[at]univ-grenoble-alpes[dot]fr)

univ-grenoble-alpes.fr (ralph[dot]gros[at]univ-grenoble-alpes[dot]fr)

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn